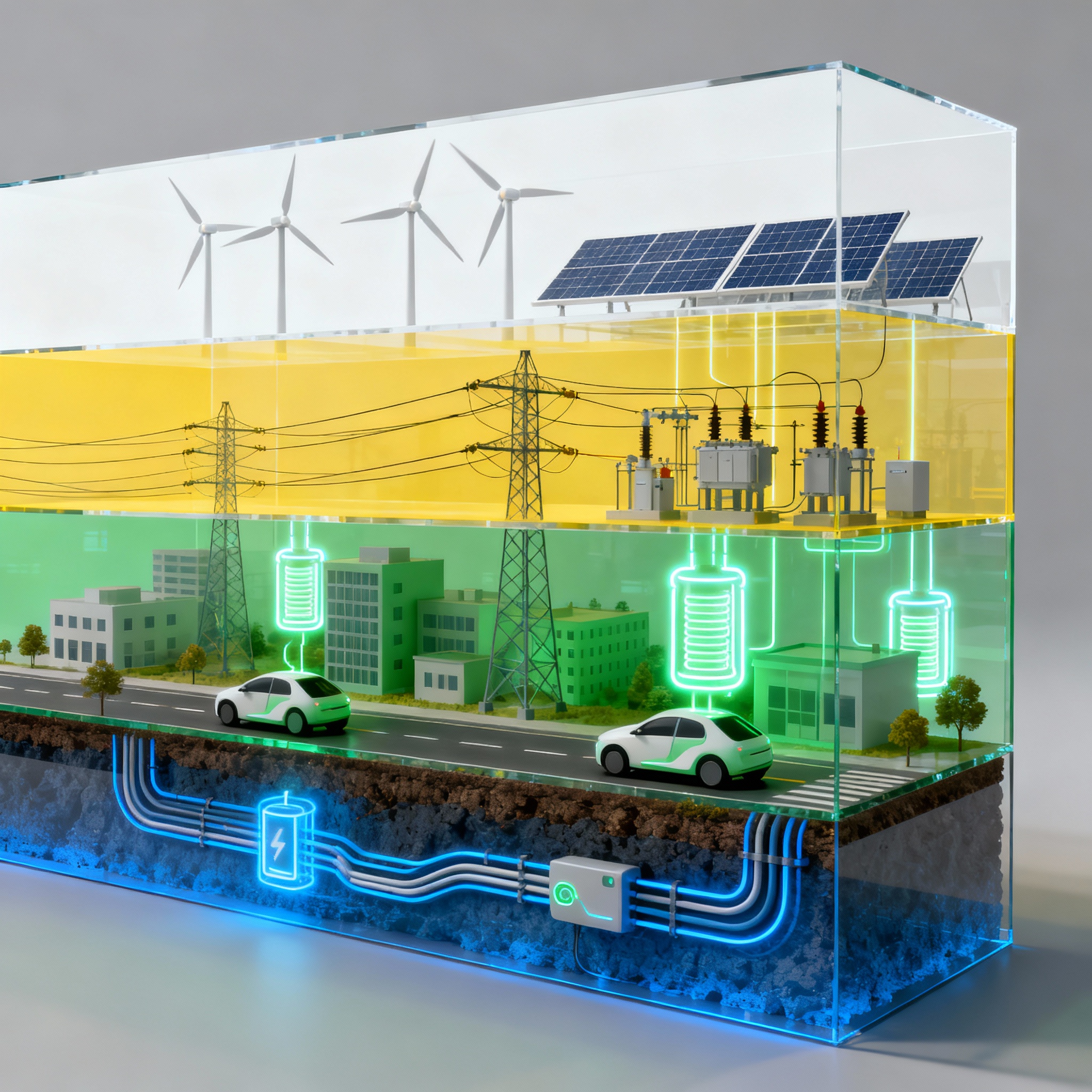

Beyond Storage —

Building Energy Infrastructure for Generations

In the world of energy, hundreds of storage concepts compete for attention.

Aestus stands apart — not as another battery technology, but as a foundational energy infrastructure platform.

We’re part of the long‑duration energy storage revolution, but we extend it further.

Our system stores, stabilizes, and supports power and heat, coupling the dependability of infrastructure with the flexibility of renewables.

Using long‑life ceramics, a closed thermal cycle, and modular configurations, Aestus delivers continuous, safe, affordable power with thermal integration that enables HVAC and cogeneration capability — reshaping how industry, utilities, and data centers manage energy.

This isn’t incremental improvement.

It’s an infrastructure‑grade evolution designed to last until 2070 and beyond.

Others give you energy storage.

We give you energy infrastructure.

Superior Safety Profile with Zero Fire Risk

Aestus’s closed-loop thermal system eliminates the single biggest concern plaguing lithium-ion batteries: thermal runaway and fire hazards. While the industry reports over 25,000 battery fire or overheating incidents in the US between 2017-2022, Aestus uses inert gas in a closed environment with no flammable materials, toxic chemicals, or dangerous emissions. The system operates with abundant earth ceramics as storage media—materials that cannot combust—providing inherent safety advantages critical for urban installations, substations, and behind-the-meter commercial applications.

Exceptional Longevity with Zero Performance Degradation

Aestus offers a 50 years operational lifespan with virtually zero performance degradation, a stark contrast to lithium-ion batteries that experience 2.9% annual capacity fade and typically require complete replacement after 7.5-10 years. Battery systems must be oversized upfront to compensate for inevitable degradation, and their heat generation characteristics worsen significantly with age. Aestus’s ceramic heat sink operates at temperatures up to 950°C without material deterioration, maintaining consistent performance throughout its lifetime.

Supply Chain Independence and Domestic Sourcing

While China controls 94% of LFP battery production, 70% of processed lithium, and 80% of raw material refining capacity for lithium-ion batteries, Aestus uses 100% abundant earth materials—primarily cordierite ceramics, carbon steel, and inert gases. These materials are domestically available with no reliance on concentrated supply chains vulnerable to geopolitical disruption. This represents a fundamental strategic advantage as battery supply chain constraints intensify, with China now implementing export controls on battery components and manufacturing equipment.

Complete Circular Economy with 100% Recyclability

Every component of the Aestus system is 100% recyclable with no toxic waste streams. In contrast, lithium-ion batteries present significant end-of-life challenges—only 51% of cobalt and 42% of nickel can potentially be recovered by 2040, while toxic electrolytes, thermal management fluids, and degraded cathode materials create disposal problems. Aestus’s ceramic, steel, and inert gas components can be fully reclaimed and repurposed, aligning with circular economy principles without environmental remediation costs.

Modular Scalability with Compact Footprint

The Aestus system achieves approximately 1/10th the footprint of equivalent power battery installations, delivering 2MW power with 25MWh storage capacity in a highly compact, modular configuration. Aestus has the ability to daisy chain several of these systems together to increase more storage as required. The 2-meter diameter heat sink vessels can be flat-bed shipped within standard truck envelopes and positioned with rubber tire cranes, enabling flexible site deployment. While battery systems also offer modularity, they require significant space for thermal management systems, fire suppression infrastructure, and safety spacing between containers—constraints Aestus avoids entirely.

Economic Advantages: Lower LCOE and No Replacement Costs

Aestus delivers over 70% round-trip efficiency with minimal operating costs and no major component replacements. Other battery storage systems face substantial ongoing expenses: fixed O&M costs of 2.5% of capital annually to address degradation, plus complete battery replacement representing 40-60% of initial capital costs at the 7.5-10 year mark. Techno-economic analysis across seven power markets found that Aestus achieves positive NPV in over 50% of nodes while projected 2030 lithium-ion systems lose money due to high capital expenditure and replacement requirements.

Proven Grid Services with Rapid Response

The Aestus system provides fast ramp-up with almost instantaneous power delivery and operates at 100% rated useable power with configurable discharge up to 10+ hours. While batteries excel at sub-second response for frequency regulation, Aestus offers comparable rapid response while simultaneously delivering the long-duration storage (8+ hours) increasingly required as renewable penetration grows. The closed Brayton cycle architecture achieves efficient thermodynamic performance with round-trip efficiency above 70%, competitive with battery systems’ 75-90% efficiency when considering Aestus’s superior calendar life and absence of standby losses from thermal management.

True Long-Duration Energy Storage Without Energy Decay

Aestus can maintain discharge capacity after 5 days of storage, addressing the multi-day and seasonal storage requirements that batteries cannot economically serve. Lithium-ion batteries experience continuous self-discharge and require active thermal management even when idle, consuming energy and degrading capacity. Aestus’s well-insulated ceramic heat sinks retain thermal energy with minimal losses over extended periods, making it viable for applications requiring weekly or seasonal energy shifting—use cases where battery LCOE becomes prohibitively expensive.

Why Aestus Is Different

- 50 + years of life — double or triple the duration of other technologies

- 0.5 % O&M per year — at least 8 × lower than typical systems

- 100 % performance retention — no fade, no degradation

- Thermal + Electrical Output — one system for energy and HVAC support

- 100 % U.S. Supply Chain — no tariff risk, no critical‑material exposure

- Modular, Compact, and Scalable — from 2 MW to 25 MW + installations

- Zero fire risk, zero runaway — ideal for dense industrial or urban sites

- Fully recyclable circular materials — a complete life‑cycle solution

The Last Energy Storage System You’ll Ever Need

50-year operational life. 0.5% maintenance costs. Dual energy storage + industrial heat. 100% American supply chain.